- Your neighbor

- BYK.com

The application areas are versatile and so are the required additives. BYK additives provide you solutions for pigment stabilization, defoaming, improved surface properties and rheology control in aqueous, solvent-borne and solvent-free formulations.

BYK is your expert technology partner when it comes to purposefully improving the properties of your adhesives and sealants. BYK offers additives for all kinds of adhesive systems, from aqueous dispersion adhesives to solvent-borne systems or solvent-free reactive systems such as polyurethanes, epoxides, acrylates and silane-terminated polymers. In addition, BYK is continuously expanding its range in the field of hot-melt adhesives.

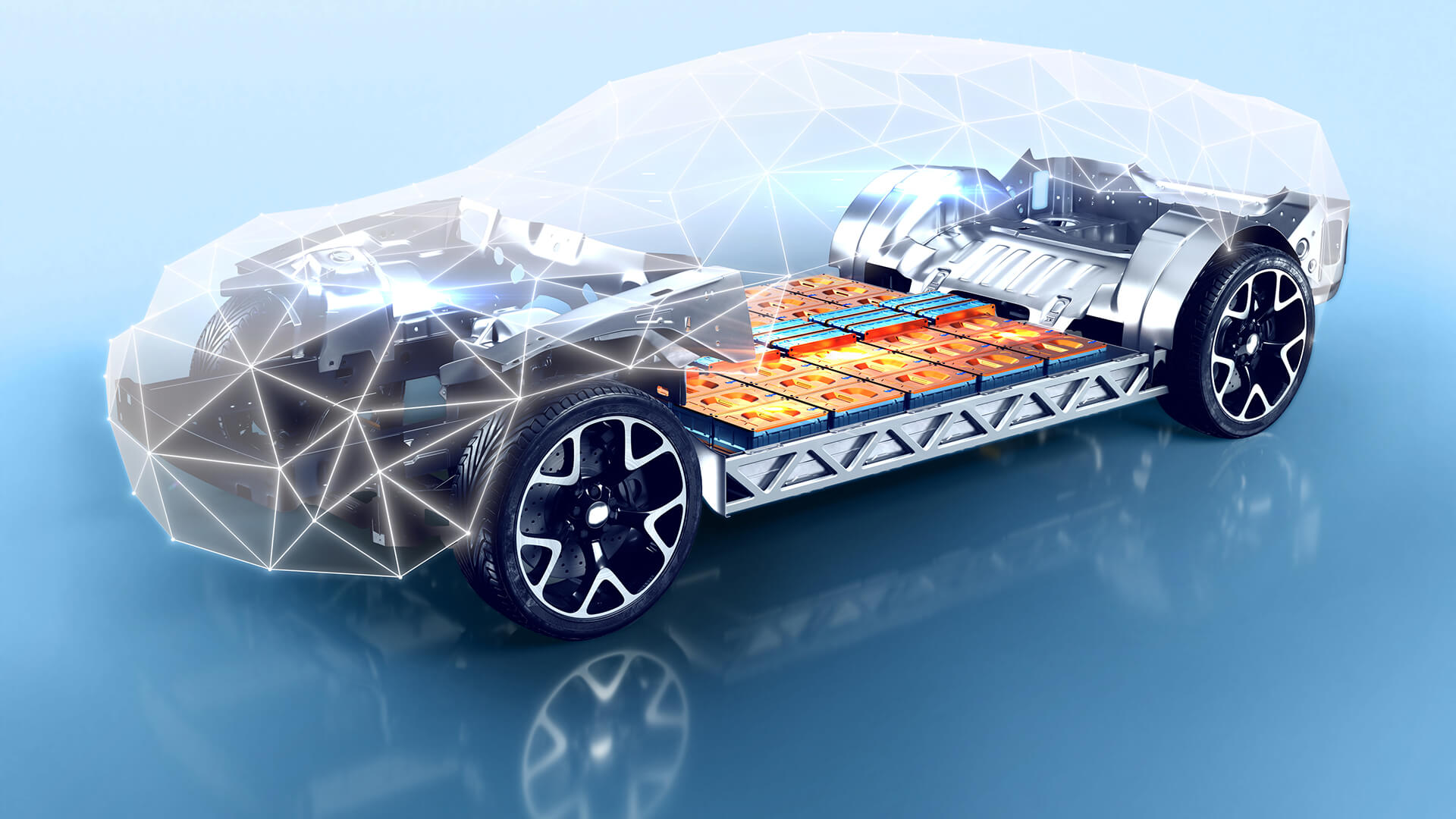

BYK additives for supercapacitors, Li-ion batteries, and fuel cells improve your production process and product properties. Some of the key-steps during the production of supercapacitors, Li-ion batteries and fuel cells are relying on the dispersion of particles, the control over interfaces, as well as the accurate coating of substrates. Therefore BYK additives can create value for our customers in the area of electrical energy storage and conversion. In this field our research focus lies on Li-ion cells. BYK delivers products for the manufacturing of electrodes and ceramic coated polyolefin separators which contribute to save production costs as well as improving the product properties and safety of the cells.

Bentonite based clays play an important role in many formulations for the foundry and refractory industry. As binders in mortars or ramming mixtures, the BENTOLITE grades stand out for their very low ferrous/iron content. Foundry coatings require a unique set of properties where BYK additives can help to balance substrate wetting, defoaming and rheology behavior of the foundry coatings.

BYK offers solutions for the challenges of surface cleaning, surface care and fabric care for household, industrial and institutional cleaners applications. BYK additives optimize the rheology adjustment of cleaners and detergents and that of surface properties, along with substrate wetting and foam prevention. BYK offers a range of additives for household and commercial polishes, cleaners, detergents and fabric softeners for both aqueous and solvent-borne cleaners and care products.

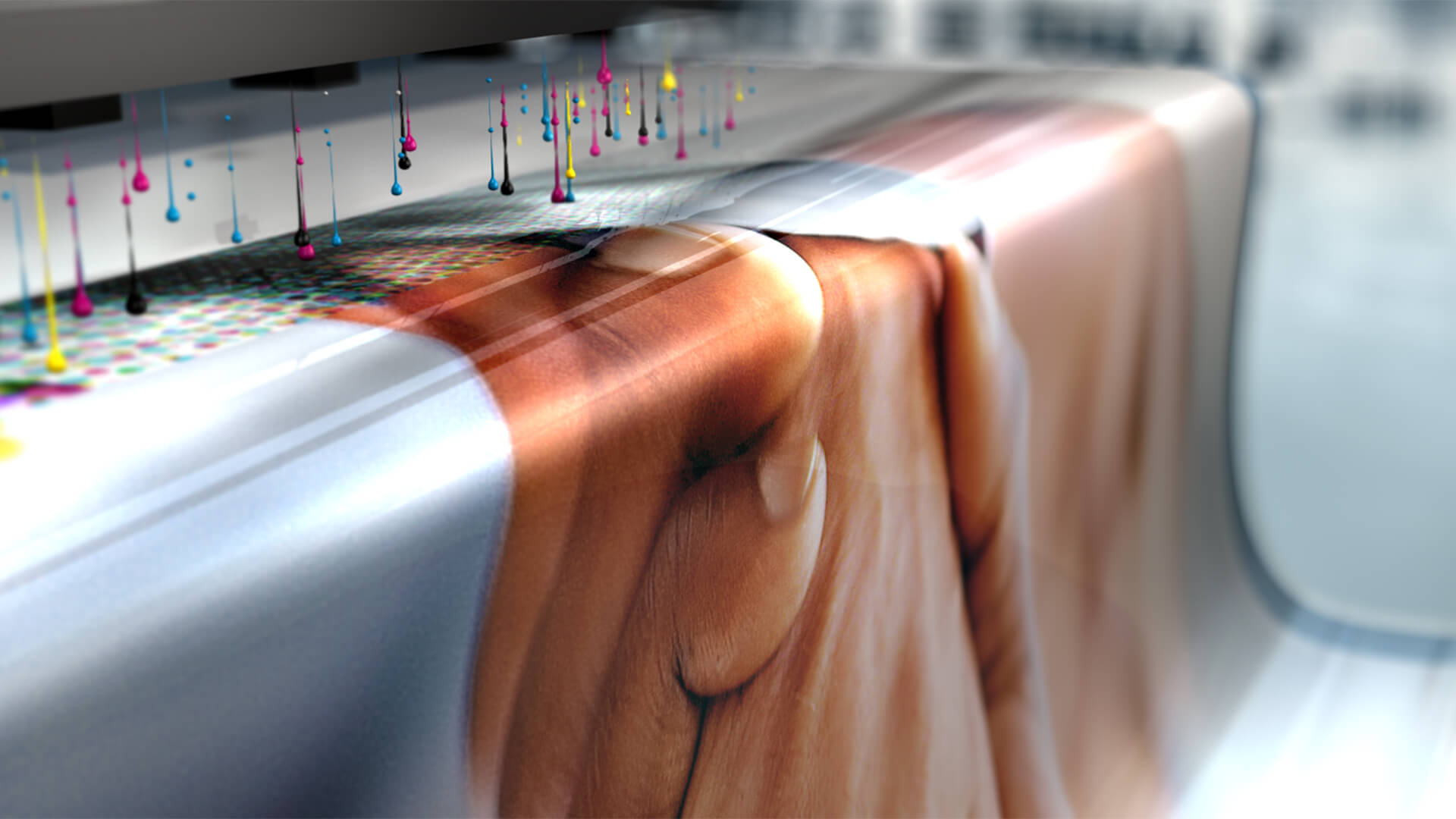

Inkjet printing is becoming increasingly important in many areas in which substrates have traditionally been printed using exclusively conventional means, e.g. in packaging printing on paper, cardboard and foil, on ceramic substrates or on textiles. For all applications, BYK offers the fitting additives to support the formulation of inkjet inks, even in areas in which indirect contact with food is required. BYK additives ensure low-viscosity and long-term stable inkjet inks with optimum color strength, improve the jetting properties and abrasion resistance of aqueous, radiation-curing, solvent-borne and ceramic inkjet inks.

Industrial lubricants consist of a base oil and different additives. Those additives are responsible for the improved performance, and they transform a “simple” base oil into a high-performance lubricant. BYK offers different additives for industrial lubricants. Our defoamers can be used to prevent foam generation, and to release air from the lubricant. BYK wetting and dispersing additives can be used to suspend solid additives (e.g. graphite, MoS2). Higher solid concentrations can be achieved. BYK rheology additives can be used to tailor the flow behavior of the lubricant. They have a positive effect on the anti-settling behavior of solid particles such as graphite, while our surface additives improve substrate wetting.

Paper coating and converting impart special qualities to the paper surface to deliver a performance not exhibited by the uncoated base paper. In all cases additives and functional reagents are required to deliver an optimized paper surface and the required performance. BYK offers additives that can assist in the preparation of the coating color, improve the coating process, and enhance the paper surface. The range of products available ensures that specific requirements, such as compliance with global regulations for food contact, can be considered and satisfied in developing the optimal solution.

Printing speeds in conventional printing are becoming ever faster, with a corresponding increase in the demands on the printing inks used. BYK additives help meet these increased requirements and develop the optimum printing inks. Whether to improve the color strength and transparency of a printing ink, to improve the abrasion resistance of printing inks and overprint varnishes, for efficient defoaming or to improve the wetting behavior – BYK offers the fitting additives for aqueous, solvent-borne and radiation-curing systems. Of course, they are also suitable for food contact applications according to certain regulations.

If you delete your search history, all your previous searches will be deleted permanently.